Valves

Learn about our preferred vendors & Trinvalco Solution Champion

Curtiss-Wright Valves

Brecksville, Ohio

https://www.cw-valvegroup.com/

Solution Champion

Ian Dass

ian.dass@trinvalco.com

Farris

Farris

Since the 1940s, Farris Engineering has designed and produced a wide range of spring-loaded and pilot-operated pressure relief valves. Used as safety devices, PRVs prevent over-pressurization of vessels, pipelines, and equipment, protecting employees, plants and the environment.

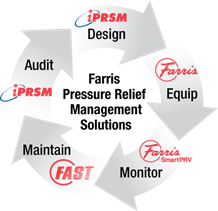

With Farris, a trustworthy valve is only part of our promise. Farris provides customers with total pressure relief management solutions that support a facility’s entire lifecycle, transforming the way you ensure plant safety:

Design – Using the power of iPRSM technology and our Farris Engineering Services team, correctly design your pressure relief system to respond to every overpressure scenario.

Equip – Equip your plant with Farris’ full line of spring loaded and pilot operated PRV hardware, knowing your plant is protected by 70 years of manufacturing experience.

Monitor – Monitor your pressure relief valves with the Smart PRV and leverage the technology of proven leaders, Farris and Emerson.

Maintain – Localized aftermarket service and repair assistance through the Farris Authorized Service Team – or “FAST” centers.

Audit – Our Farris Engineering Services Team and iPRSM technology will keep your pressure relief systems audited and in compliance.

Farris Engineering Services – Farris Engineering Services provides processing facilities with expertise in overpressure scenarios and relief system performance, helping you to design and audit relief systems for a safer plant environment. FES is a critical part of the Farris total pressure relief management solutions that support a facility’s entire lifecycle.

Daume Regelarmaturen

Daume Regelarmaturen is a premier supplier of highly engineered, critical service valves for the regulation of Gas, Water & Steam.

Located in Isernhagen, near Hanover Germany, Daume focuses on the design, development and supply of critical service control valve products for the Conventional and Nuclear Power Generation markets.

Phonix

Phönix has supplies a wide variety of valve products, including on-off and control valves for critical system in the Chemical/Petrochemical, Power Generation and a number of other specialty industries, highlighted by our bellows sealed valves. Our commitment to customer satisfaction and quality products is integral to meeting customer needs.

The wishes of our clients for quality and timely provision of their orders (customer satisfaction) are defined highest requirement of our economic acting. Thus, we observe relevant regulations, laws, ordinances, rules and the generally accepted engineering standards and customer requirements in our daily work.

Solent and Pratt

Solent & Pratt is at the forefront of the design, development and manufacture of high quality butterfly valves for engineering projects around the world. An absolute commitment to outstanding quality and reliability is the key of our success, particularly in severe service environments. designer/ manufacturer of high performance butterfly valves for severe service applications.

Acquired in 2001 by Curtiss-Wright Flow Control, Solent and Pratt, based in the U.K., is a world leader in the manufacturing of high performance valves. These application critical valves are currently supplied to the oil and gas market, specifically to oil producing applications at offshore oil rig installations.

Strack

For nearly one-hundred (100) years, Strack has been a prominent supplier of high quality critical service and high pressure valve products designed, manufactured and tested to the most advanced industry requirements in all industries served.

Strack GmbH has been established in 1922, in Troisdorf, Germany, as a small privately owned company and is one of the most prominent manufacturers of high quality valves in the world. Through the eighty years of our existence, we always strove to develop a product line based on the most advanced requirements of the industry.

Arca Regler

Kempener Str 18 D-47918

Tönisvorst , Germany

https://www.arca-valve.com

Solution Champion

Narin Sookdeo

narin.sookdeo@trinvalco.com

Since its founding some 99 years ago, ARCA Regler has earned global recognition with its innovative technology and proven quality.

The pneumatically and electrically-activated control valves we manufacture are sought-after products for use in industry. They have many applications – from power station construction to chemical plants, from pharmaceutical and foodstuff production to steelworks.

Over the years grown to a company group, that besides valves also manufactures pumps, cryogenic components and visual level indicators, we offer solutions for your specific needs. As a second-generation family-owned company, we’ve won the trust of our customers and proven our worth time and again. Round about 500 employees help us doing so with their full commitment.

Thanks to a global network of representatives and joint venture partners, and local offices in India, China, Korea, and Mexico, we are able to provide our customers around the world with reliable and innovative technology tailored to their personal needs.

Our success is also evident from the awards we have received to date, including placement in the TOP 100 and TOP JOB lists. We have also been a finalist in the Award for Midsized Enterprises, and various design prizes have been awarded for ARCA products.

Put us to the test – let us show you what we can do for your company!

Zwick Armaturen GmbH

Hauptanschrift

Egerstraße 1, Germany

https://zwick-gmbh.de/?lang=en

Solution Champion

Karl Lall

karl.lall@trinvalco.com

ZWICK is a leading manufacturer of valves which meet highest requirements and quality standards. The product range contains metal-seated butterfly valves known as series TRI-CON, the check valves series TRI-CHECK and the TRI-BLOCK series, ZWICK’s Double Block and Bleed Design.

30 years experience in design and production of valves guarantee high standard products. ZWICK valves are produced state-of-the-art. The triple offset butterfly valves are specially designed for critical services where they are used as shut off and control valves. The in-house design enables offering customized solutions for individual applications like the global Industries of Oil and Gas, Chemical, Petrochemical, Energy, Offshore and Steel. TRI-CON valves incorporate a unique third offset design with a true cone-in-cone seating and a reliable zero-leakage performance and allow bi-directional tightness.

The ZWICK self-centering disc design that is keyed to the shaft accommodates differential thermal expansions of the disc and the shaft. The triple offset geometry assures friction free running without radial loading of the seal ring and break-away torque. The TRI-CON series reaches a superior unrivaled life time cycle. For critical services a patented sealed bearing solution is offered to prevent fouling of the bearing associated with line media. ZWICK’s zero-leakage bearing design assures that no line media will migrate into bearings cavity. TRI-CON’s standard graphite packing meets all requirements of TA-Luft for fugitive emissions from the shaft and packing arrangements. All triple offset valves are certified according to Fire-Safe to API and British Standard.